When it comes to custom goalie pads, nobody does it better than Vaughn Hockey. Recently, Vaughn gave us a behind the scenes peek at the manufacturing process for one of our goalie customers, Casen Janko of Matignon High School.

The process begins with the custom design from the goalie themselves. In this case, Casen went with a vintage cali-tan set up, which mimics the original leather look that we sold back in the 1980s!

Vaughn brings the pad to life by cutting the outside design of the pad wrap, and hand-stuffing it with high density foams. The goalie pad is tightly sewn back together to give a rigid and firm shape for unmatched durability.

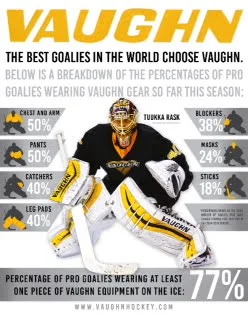

The hand-made process allows for an extreme attention to detail, which creates consistently high quality goalie pads. When we visited Vaughn Custom Sports in Oxford, Michigan it became clear that owner Mike Vaughn cuts no corners when it comes to making goalie equipment. He routinely checks the quality of the materials that go into his goalie pads himself in his personal workshop. Trust us- we’ve seen it firsthand; the same effort and attention to detail goes into making a pad for Tuukka Rask or Jonathan Quick, as it does for any customer off the street.

The resulting product for customers like Casen Janko is the reason that goalie customers keep coming back to Vaughn, and it is the reason why nearly 77% of NHL goalies are wearing at least 1 Vaughn goalie product.

Location:

Location:  Phone:

Phone:  Email: info@sportsetc.net

Email: info@sportsetc.net